CNC Machining

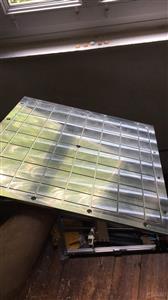

Sheet Metal Fabrication

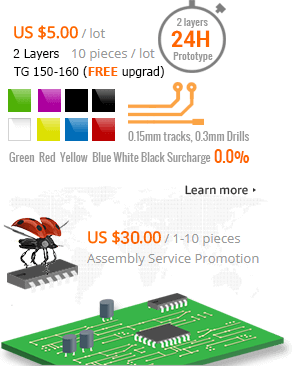

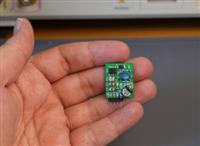

Additional Services

Materials

Metal

Reviews

Engineering Guides