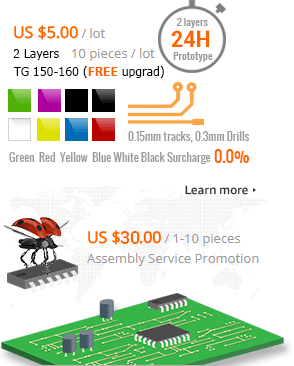

PCB Prototype the Easy Way

Full feature custom PCB prototype service.

Help Center

Service hotlines

+86 571 8531 7532

9:00 - 18:00, Mon.- Fri. (GMT+8)

9:00 - 12:00, Sat. (GMT+8)

(Except Chinese public holidays)